Not a great day – the Imperial died in the middle of a test drive and had to be towed home.

As a break from the electrical work covered in Electrical 5: Boxing I had decided to put some miles on the car to break in the engine and suspension and to try to work out a problem with losing power under acceleration. Bad idea! The loss of power got steadily worse, ultimately stopping completely in the middle of the road. Fortunately I had gotten off the Interstate and was looking for a place to park. Unfortunately I hadn’t found that place when it quit completely.

Fortunately a kind gentlemen in a pickup truck (hi, Ken!) stopped and asked if I needed help getting towed off the road. He hooked up a tow strap and pulled me 1/4 mile over the top of the hill and into the parking lot of Westward Orchards in Harvard.

First things first, so I headed in to the store, bought a coffee, told them I had broken down, and asked if it was OK to stay in the parking lot for a while. “No problem!” was the answer – this was a case where it was better to ask permission than forgiveness. OK, this was actually the second thing – the first thing was thanking Ken profusely for his help!

There wasn’t a trace of gas in the fuel filter – bone dry. This confirmed my suspicions of a fuel delivery problem. Looks like a blockage in the lines or a bad fuel pump. Or maybe air leaking into the lines. Nothing that can be fixed in the parking lot, so time to call for a tow. Thanks to the miracle of cell phones this is easier than it used to be. Fortunately it only took 45 minutes for the tow truck to show up, and a half hour later the Imperial was back home.

Blocked lines don’t make any sense – the fuel tank, fuel sender, fuel lines, fuel filter, and fuel pump are all new and were working up to this point. The fuel pump is brand new with less than 100 miles on it, but it is the most likely suspect.

NAPA didn’t have any of these fuel pumps in stock, so I had to order a new fuel pump. While waiting I dug out the original fuel pump and installed it. I had replaced the original pump to avoid problems like this from happening…

With the original fuel pump back in place – nothing. Not a drop of gas. Stubbornly remains bone dry. Krud.

OK, time to troubleshoot the entire fuel system checking for blockage or leaks. All of the lines are clean, all of the connections are tight, the fuel hoses are securely clamped to their fittings, and the fuel tank vent is fine. Blowing air through the lines showed that they are open with no trace of blockage. In fact, after I removed the input line from the fuel pump gasoline continued to dribble out of the line, siphoning from the gas tank. Clearly gas is getting to the fuel pump. The fuel filter and lines to the carburetor were checked and were also open.

Once again the evidence is pointing to the fuel pump. And I have another new pump on order. But this still doesn’t make sense – failure of two pumps that were working is unlikely…

Sigh. More diagnostic work is needed. I’ll update the Blog when I find something.

Update (12July2021)

Some online research revealed that a common problem is wear of the pushrod that goes between the camshaft and the fuel pump. This pushrod connects the fuel pump lobe on the cam to the pump lever in the fuel pump.

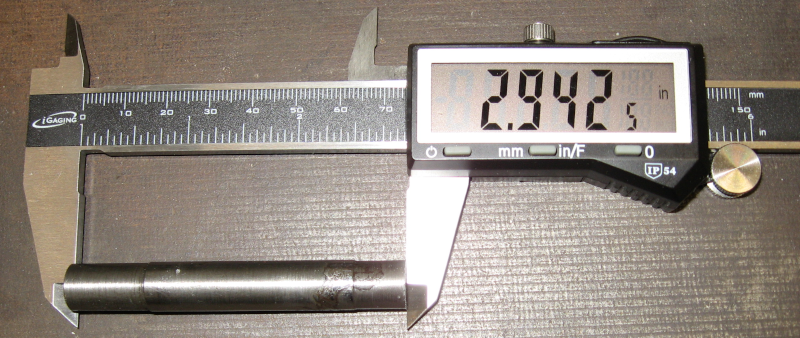

The pushrod is supposed to be 3.22″ long. It is fairly easy to remove – remove the fuel pump, unscrew the retaining plug, and the pushrod drops out. OK, it drops out after grabbing it with needle nose pliers and wiggling it a bit…

Fire up the trusty digital calipers and measure the length: 2.942″. The pushrod has worn 0.278″ – over a quarter inch of wear! You can easily see the wear – there is a thicker section in the middle of the pushrod that rides in the bore and reduced sections at each end. These end sections should be the same length. You can clearly see that the right side is shorter than the left side. You can also see some wear toward the right side of the middle section.

There is no way the fuel pump could work with this much wear – it is amazing that it worked at all! The pushrod should have been replaced when the engine was rebuilt; I’m disappointed the shop didn’t do that. If I ever rebuild another Chrysler big block I will know to check the pushrod while the engine is out of the car. Or better yet just replace it as another wear part in the engine.

A new pushrod is on order. Hopefully this is the only problem; wear on the camshaft would be really bad. Will update again after the new pushrod is installed.

Update 2: 29July2021

After a bit of a comedy of errors (my errors…) the new fuel pump finally pushrod showed up. Installation of the pushrod and fuel pump was actually quite easy. Then the moment of truth:

Crank the engine over for several seconds. Go to check the fuel filter. And there was gasoline in the fuel filter! Crank the engine some more and it started and ran. And there was much rejoicing!

At this point I changed the oil and filter in case there was any metal from the pushrod in the oil.

Fired the engine up and drove the car around the block a couple of times. It is running great! Running smoothly, plenty of power, and no hesitation. I had other commitments and couldn’t spend much time driving the car, so putting some quality miles on it will have to wait for another day.

On another note, all of the electrical wiring is working (see the thread on Electrical for details). This is a pleasant surprise, as I had expected to have to track down and fix at least a few mistakes.