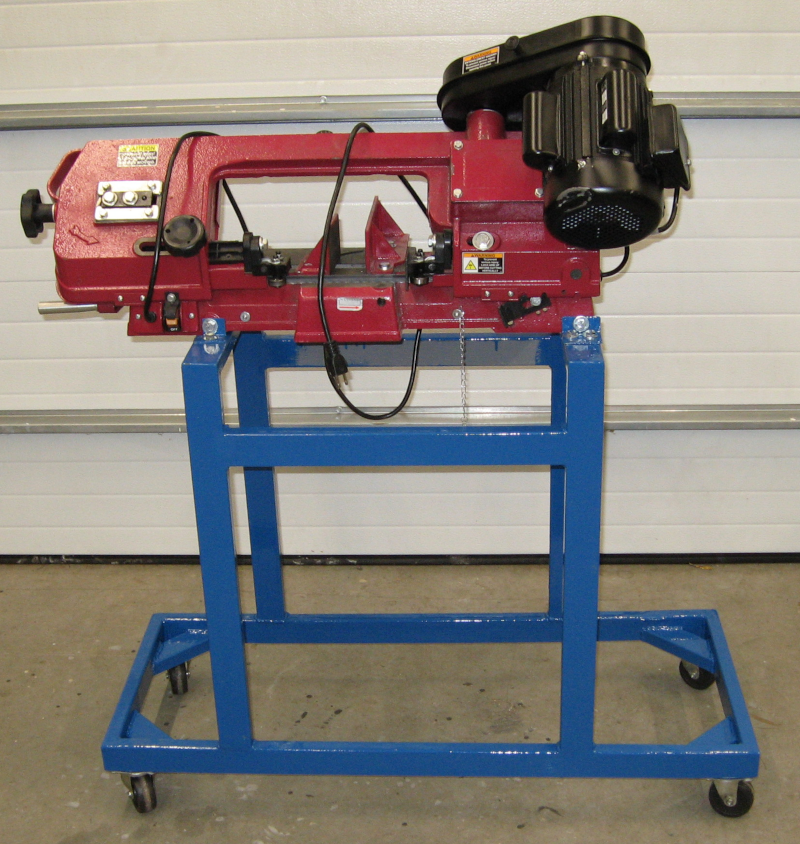

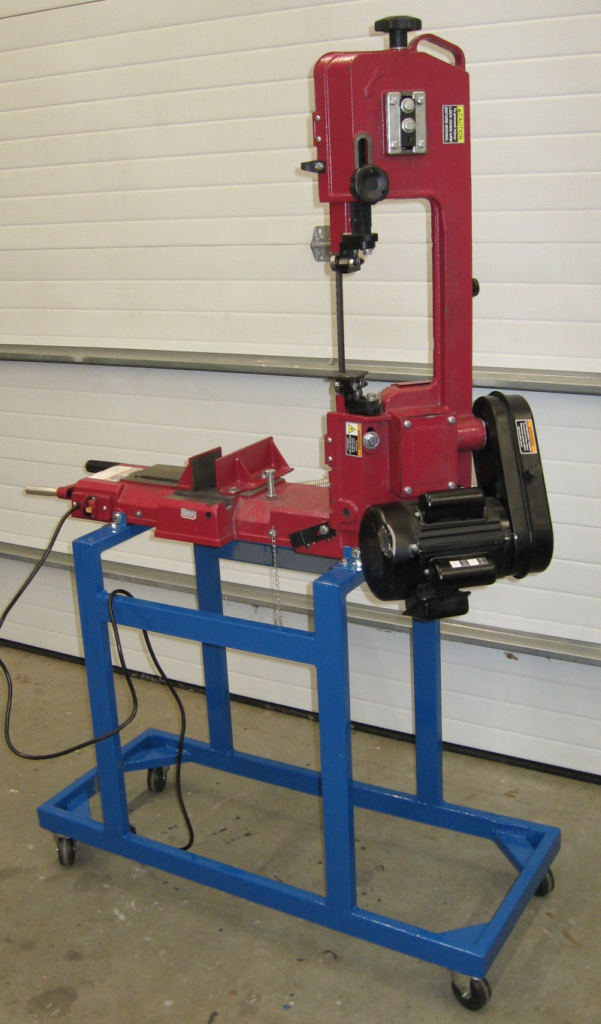

The horizontal bandsaw has been getting a real workout cutting up the steel tubing for various projects. While it does a good job cutting there are issues – mostly with the stand.

The included stand is the most criticized part of the bandsaw: it is flimsy, provides marginal support when the bandsaw is used in the vertical position, and is too low. In addition it is somewhat difficult to move the 140 lb. saw around.

The biggest issue is that it is too low. Since the main use is cutting up long pieces of stock you usually have to support the other end of the stock. I have a set of roller stands I use with the table saw, chop saw, drill press, and fabrication table for just this purpose. Unfortunately the lowest position on the roller stand is higher than the bandsaw. I ended up quickly welding together a temporary stand just for the bandsaw. This temporary stand is clumsy, awkward, and difficult to store – I’m looking forward to cutting it up and returning it to the stock pile!

All of these issues can be addressed with a new stand. The base was sized for stability – both side to side and when using the saw in the vertical position. The height was set to ensure that the roller stands can be used. And casters make it easy to move around.

There are still a few things to do: First is adding a piece of plywood to the base for storage. Second is to add a pan to catch the metal particles from cutting and make cleanup easier.

Next: getting back to actually working on the car with What’s Behind Door Number One?