With the boat running right after the previous article on Flat Mercury we can move back to getting the Imperial ready for paint.

The doorcards – the covering on the doors inside the car – needed to be removed to work on windows and for paint. Unfortunately the inside door handles are attached to the doorcard and come off with the doorcard – meaning you can’t open the doors from the inside. I’ve been working around this for months, being careful not to shut myself inside the car. Fortunately I never did this – nope, not once. Never happened. Never made the mistake of closing all the doors while I was inside. Nope, not at all. This especially never happened when the battery was disconnected, making it impossible to lower the window and use the outside door handle. Trust me, never happened.

Ahem.

Anyway, I needed some way to open the doors from the inside. While considering several excessively complicated ways of making a handle I happened to contemplate my scrap steel box.

Hmm, those cutoff end pieces of steel tubing from a variety of earlier projects might just work…

A quick measurement says a 1/2″ hole will just fit over the door handle shaft. Setup the drill press and a 1/2″ hole magically appears:

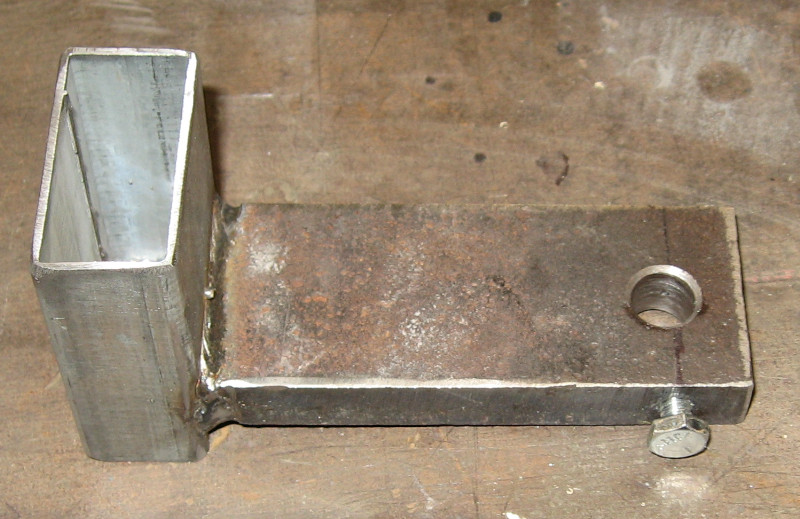

Locking the door handle to the shaft is easy – flip the new handle on its side and drill and tap for a 1/4″ bolt:

All that is left is to slip the new handle over the shaft and tighten the locking bolt:

Lather, rinse, and repeat three more times and I don’t have to worry about locking myself inside the car again! Which never actually happened, of course…

Confession

I take safety seriously. Pain hurts and I don’t like the sight of my own blood. But I slip up from time to time.

The most dangerous phase while drilling holes is when the drill bit breaks through the back edge of the part. The drill bit can catch and grab, pulling itself into the part. When using a hand drill it may just stall the drill. I’ve mentioned that this industrial drill press doesn’t stall…

I had the part clamped in the drill vise and had a good grip on the vise. No problem for the first 98% of the hole. Unfortunately, when the drill broke through the back of the 5/8″ thick steel part it grabbed and started spinning.

The vise was ripped out of my grasp, dragged the part up the drill bit, and EVERYTHING started spinning – both the part and the vise. The part plus vise was widely out of balance and promptly snapped the 1/2″ drill bit and sent the vise plus part plus one half of the drill bit flying through the air.

Fortunately the vise flew away from me – missing me completely and hitting the drill press where it left a large gouge in the massive cast iron base. Somehow my hand holding the vise wasn’t hurt. The drill press was running at fairly low rpm – but still fast enough to do plenty of damage in a fraction of a second.

I got lucky. Really lucky. I wasn’t hurt, the vise is actually OK, and the damage to the drill press is cosmetic. The only thing actually broken was an $8.00 drill bit, making this a very cheap lesson!

The drill press table is set up so that the vise can be bolted to the table. If you look at the second picture you can see how the vise is bolted down. As it will be when I use the drill press in the future!

Next: while the Imperial waits for paint let’s tackle home renovation with A Room for Three Seasons.