So I was perusing CraigsList…

That introductory line is right up there with “hold my beer” as an indicator that things are about to get interesting!

I’ve been wanting a specific set of tools to expand my sheet metal fabrication capabilities.And here was a listing for the four tools I most wanted. For $200 for the set. Road trip! Well, if you can call 40 miles a road trip…

Bead Roller

A bead roller is used to put various types of grooves and raised areas inside sheet metal panels, usually for stiffening. It can also be used to put flanges and raised sections on the edge of a panel, and is one of the few tools that can handle curved edges.

English Wheel

An English Wheel is a specialized piece of equipment that produces smooth curves in two directions. In the hands of an expert it can produce amazing shapes with great accuracy. I’m no expert but I did learn the basics of using an English wheel in the coachbuilding course I took a couple of years ago.

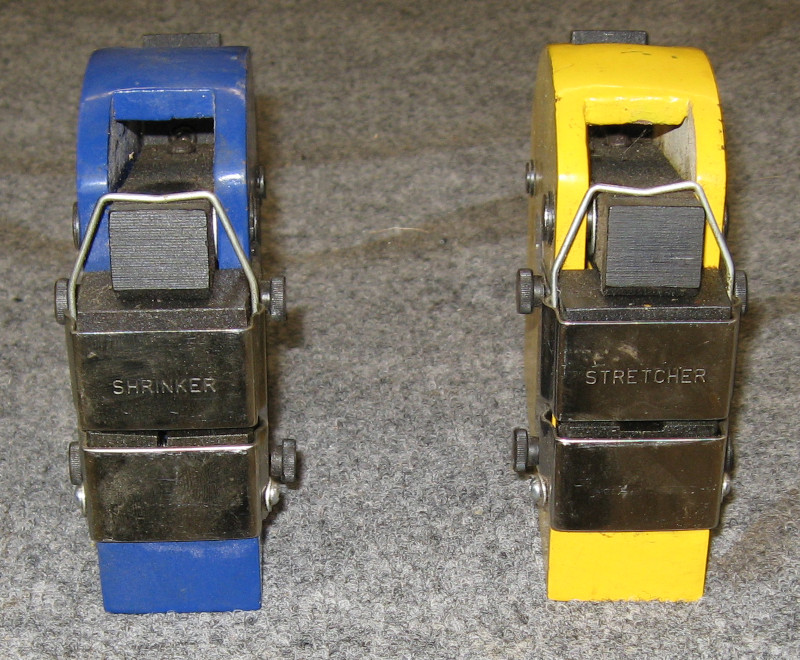

Shrinker/Stretcher

The basic use of a shrinker/stretcher is to allow making curves in flanges. The most widely used alternative is to cut pie shaped wedges in a flange and then curve it. In many cases you then have to weld up the gaps in the flange which is a lot of work. A bead roller and shrinker/stretcher would have been a big help when working on the Imperial doors.

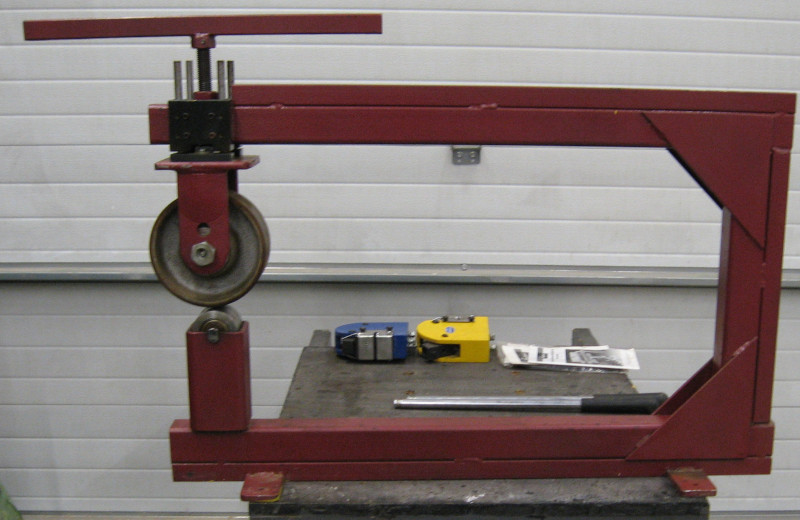

Bench Shear

A bench shear produces highly accurate cuts in sheet metal with little distortion for both straight lines and curves. You feed the sheet metal through the shear allowing long cuts.

A bench shear is easier to use and more accurate than aviation snips, faster and often more accurate than sawing, and produces far less mess than using a cutting disk. It is extremely fast requiring no setup – just draw lines on the sheet metal like usual, feed it into the shear, and pull the handle.

Once I get this shear mounted on a workbench it will really speed up working with sheet metal – I’m looking forward to it!

Now to find a project where I can use these tools!